Our continuous improvement capacity has allowed us to be today the largest production plant in the world, with a production of 5 tiles per second and a stock of more than 240,000 pallets. How we got here, we tell you in this section.

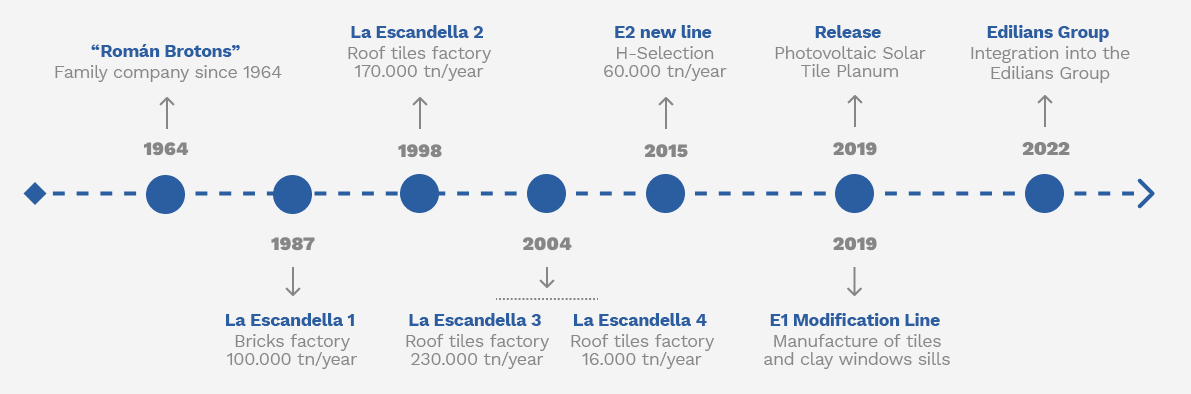

In 1964, Francisco Noé Román and Juan José Román founded the first ceramic flooring factory. Today, thanks to quality, innovation, the studied clay composition and the latest technology, La Escandella has managed to position itself as the largest ceramic tile production plant in the world.

The tiles of La Escandella are the result of a special formulation of atomized clay. Our team, in continuous formation, together with the application of new technologies in all our processes, allow us to move forward with firm step. We have more advanced facilities in the industry, and a fully automated production process. Our customers can visit our showroom and learn firsthand the step of how we bring our products to life.

In just two decades, La Escandella has become a leader in the national market, developing innovative manufacturing processes and new products, capable of adapting to the needs of the habitat, culture and environment of those countries and markets in which it participates.

The multidisciplinary team that makes up the staff of La Escandella, has been a very important part of everything achieved by the company in recent years.

Each one of them makes it possible that La Escandella, day after day, remains a reference in the industry, both nationally and internationally.

If you want to be part of the team do not hesitate to attach your CV. We will value your candidacy and we will answer you as soon as possible.

Today the products of La Escandella are present in a large number of iconic sites worldwide that require tiles of the highest quality to crown their constructions.

The maintenance and protection of the environment means a constant commitment in La Escandella; These values are reflected in a cogeneration plant that allows us to rationalise the use of energy, which in turn is environmentally friendly.

all industrial waters in the course of the production process are recovered and treated via a settling reservoir.

For the realization of our tiles, we use ceramic mixtures free of lead. They are 100% natural and 100% recyclable tiles. Tiles that cannot be sold are shredded and used in the manufacture of new tiles. This makes the process completely ecological.

Emission control La Escandella monitors and evaluates, according to the parameters of the Kyoto protocol, the co2 emitted into the atmosphere. In addition, it carries out periodic checks of diffuse, channelled and sound emissions in compliance with the parameters of our Integrated Environmental Authorization.

CERAMICA LA ESCANDELLA SA es el Responsable del tratamiento de los datos personales del interesado y le informa de que estos datos se tratarán de conformidad con lo dispuesto en el Reglamento (UE) 2016/679, de 27 de abril (GDPR), y la Ley Orgánica 3/2018, de 5 de diciembre (LOPDGDD), por interés legítimo del Responsable, facilitándole la siguiente información del tratamiento:

Fines del tratamiento: hacer partícipe al interesado en los procesos de selección de personal, llevando a cabo un análisis del perfil del solicitante con el objetivo de seleccionar al mejor candidato para el puesto vacante del Responsable.

Legitimación del tratamiento: consentimiento inequívoco mediante una clara acción del interesado (GDPR, art. 6.1.a).

Registro de currículums: le informamos de que este es el único procedimiento oficial para aceptar su currículum, por lo que no se aceptarán los currículums remitidos por otro procedimiento diferente.

Criterios de conservación de los datos: se conservarán durante un plazo máximo de un año, transcurrido el cual se procederá a la supresión de los datos garantizándole un total respeto a la confidencialidad, tanto en el tratamiento como en su posterior destrucción. En este sentido, transcurrido el citado plazo, y si desea continuar participando en los procesos de selección del Responsable, le rogamos nos remita nuevamente su currículum.

Actualización de los datos: En caso de producirse alguna modificación en sus datos, le rogamos nos lo comunique por escrito lo antes posible, con objeto de mantener sus datos debidamente actualizados.

Comunicación de los datos: se podrán tratar y/o comunicar a las empresas integrantes de nuestro grupo (cuyas direcciones figuran en esta misma página web), durante el tiempo de conservación de su currículum y para los mismos fines antes informados.

Derechos que asisten al Interesado:

– Derecho a retirar el consentimiento en cualquier momento.

– Derecho de acceso, rectificación, portabilidad y supresión de sus datos y de limitación u oposición a su tratamiento.

– Derecho a presentar una reclamación ante la Autoridad de control (www.aepd.es) si considera que el tratamiento no se ajusta a la normativa vigente.

Datos de contacto para ejercer sus derechos: CERAMICA LA ESCANDELLA SA. CALLE BELGICA, 1, – 03698 AGOST (Alacant). E-mail: rrhh@laescandella.com

PUBLICIDAD: En cumplimiento de lo previsto en el artículo 21 de la Ley 34/2002 de Servicios de la Sociedad de la Información y Comercio Electrónico (LSSI), solicitamos su consentimiento para la suscripción y envío de nuestra newsletter.

Fines y legitimación del tratamiento: envío de comunicaciones de productos o servicios a través del Boletín de Noticas al que se ha suscrito (con el consentimiento del interesado, art. 6.1.a GDPR).

Criterios de conservación de los datos: se conservarán durante no más tiempo del necesario para mantener el fin del tratamiento o mientras existan prescripciones legales que dictaminen su custodia y cuando ya no sea necesario para ello, se suprimirán con medidas de seguridad adecuadas para garantizar la anonimización de los datos o la destrucción total de los mismos.

Comunicación de los datos: no se comunicarán los datos a terceros, salvo obligación legal.

Derechos que asisten al Interesado:

– Derecho a retirar el consentimiento en cualquier momento.

– Derecho de acceso, rectificación, portabilidad y supresión de sus datos, y de limitación u oposición a su tratamiento.

– Derecho a presentar una reclamación ante la Autoridad de control (www.aepd.es) si considera que el tratamiento no se ajusta a la normativa vigente.

CERAMICA LA ESCANDELLA SA es el Responsable del tratamiento de los datos personales del Usuario y le informa de que estos datos se tratarán de conformidad con lo dispuesto en el Reglamento (UE) 2016/679, de 27 de abril (GDPR), y la Ley Orgánica 3/2018, de 5 de diciembre (LOPDGDD), por lo que se le facilita la siguiente información del tratamiento:

Fines y legitimación del tratamiento: mantener una relación comercial (por interés legítimo del responsable, art. 6.1.f GDPR) y envío de comunicaciones de productos o servicios (con el consentimiento del interesado, art. 6.1.a GDPR).

Criterios de conservación de los datos: se conservarán durante no más tiempo del necesario para mantener el fin del tratamiento o existan prescripciones legales que dictaminen su custodia y cuando ya no sea necesario para ello, se suprimirán con medidas de seguridad adecuadas para garantizar la anonimización de los datos o la destrucción total de los mismos.

Comunicación de los datos: no se comunicarán los datos a terceros, salvo obligación legal.

Derechos que asisten al Usuario:

– Derecho a retirar el consentimiento en cualquier momento.

– Derecho de acceso, rectificación, portabilidad y supresión de sus datos, y de limitación u oposición a su tratamiento.

– Derecho a presentar una reclamación ante la Autoridad de control (www.aepd.es) si considera que el tratamiento no se ajusta a la normativa vigente.

Datos de contacto para ejercer sus derechos:

CERAMICA LA ESCANDELLA SA. CALLE BELGICA, 1, – 03698 AGOST (Alacant). E-mail: rrhh@laescandella.com